还没有账号立即注册

登录即代表您已同意《leyu·乐鱼(中国)体育官方网站隐私政策》

忘记密码?登录即代表您已同意《leyu·乐鱼(中国)体育官方网站隐私政策》

忘记密码?

已有账号登录账号

Global PCB Industry Market Status

As an indispensable component in electronic products, with the continuous improvement of technology, the demand for PCBs is stable and will continue to grow. The PCB industry has become a global industry with an annual output value exceeding 50 billion US dollars. In 2018, the global PCB market output value exceeded 60 billion US dollars. Driven by the continuous development of the global electronic information industry, it is expected that the global PCB market output value will reach 66 billion US dollars in 2019. The global PCB output value is expected to be nearly 70 billion US dollars in 2020. The proportion of PCB output value in Chinese Mainland will continue to increase.

Market Analysis of China's PCB Industry

In recent years, due to factors such as increasing labor costs and environmental requirements in coastal areas, the PCB industry has gradually shifted from electronic technology developed areas such as the Yangtze River Delta and Pearl River Delta to provinces and cities with better industrial conditions in the mainland. At present, China has formed a PCB industry cluster belt with the Pearl River Delta and Yangtze River Delta regions as the core areas. According to statistics, there were about 1300 domestic PCB industry enterprises in 2017, mainly distributed in the Pearl River Delta, the Yangtze River Delta and the Bohai Rim region. The output value of PCB in the Yangtze River Delta and the Pearl River Delta accounted for about 90% of the total output value of Chinese Mainland.

In 2018, there were a total of 21 listed companies specializing in PCBs, among which 10 were listed in the world's top 40 PCB companies in China. In 2018, the global PCB growth rate was 6.0%, while in China, it was 10.0%. Due to China's huge domestic demand market, low labor costs and perfect industrial supporting facilities, it has attracted the continuous transfer of global PCB production capacity to China since 2000, making Chinese Mainland's PCB industry surpass Japan as the world's largest producer in 2006.

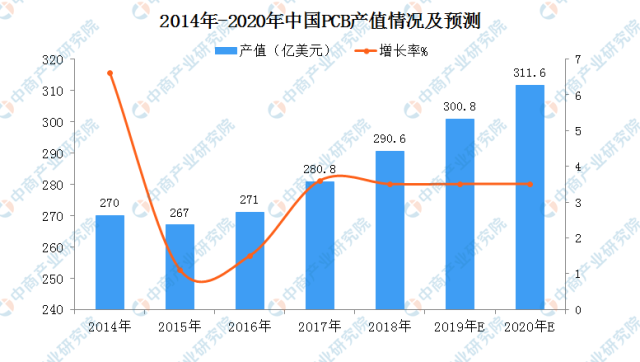

With the increasing proportion of China's PCB output value in the world, Chinese Mainland's PCB industry has entered a stage of sustained and stable growth. In 2017, China's PCB industry output value reached US $28.08 billion, and China's PCB industry output value will grow from US $27.1 billion in 2016 to US $31.16 billion in 2020, with an annual compound growth rate of 3.5%.

Data source: Compiled by China Commercial Industry Research Institute

leyu provides intelligent manufacturing related information system implementation services for PCB industry customers

With the changes in the internal and external environment of enterprises, PCB companies are facing the following challenges:

1. With the assistance of the capital market, domestic enterprises are expanding their production, resulting in fierce competition

2. Increased customer requirements for product quality traceability (Pcs traceability)

3. Competition based on delivery time response, flexible manufacturing;

4. Based on cost competition, the factory's requirements for "lean, automation, informatization, and intelligence"

5. The process of high gross profit orders is becoming increasingly complex, and improving yield has become an effective means to reduce costs and enhance competitiveness

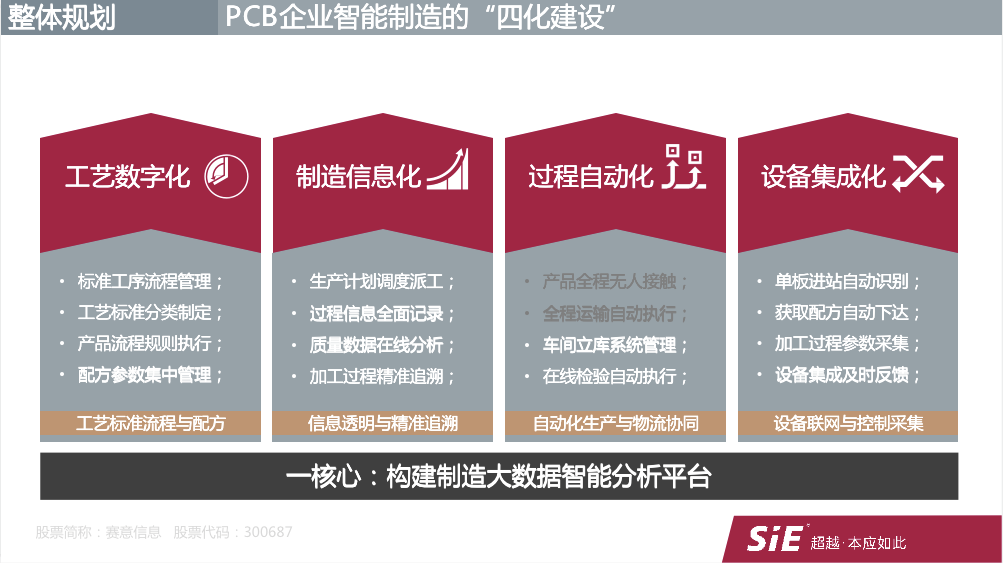

Based on the experience of implementing leyumens Camstar MES and EAP projects in typical customers in the PCB industry, Saiyi has summarized the "four modernizations" model of intelligent manufacturing for PCB enterprises. Through EAP automation and MES manufacturing informatization, it helps PCB enterprises achieve the following goals:

1. By increasing the automation rate of the factory, we can increase the per capita output value of the factory;

2. By establishing a system for process informatization, quality prevention, and parameter warning analysis, help PCB companies improve product yield;

3. By establishing an order review platform and a batch card TOC scheduling system, help enterprises increase factory production capacity (unit fixed asset output value).

The "Four Modernizations" Model of Intelligent Manufacturing for PCB Enterprises

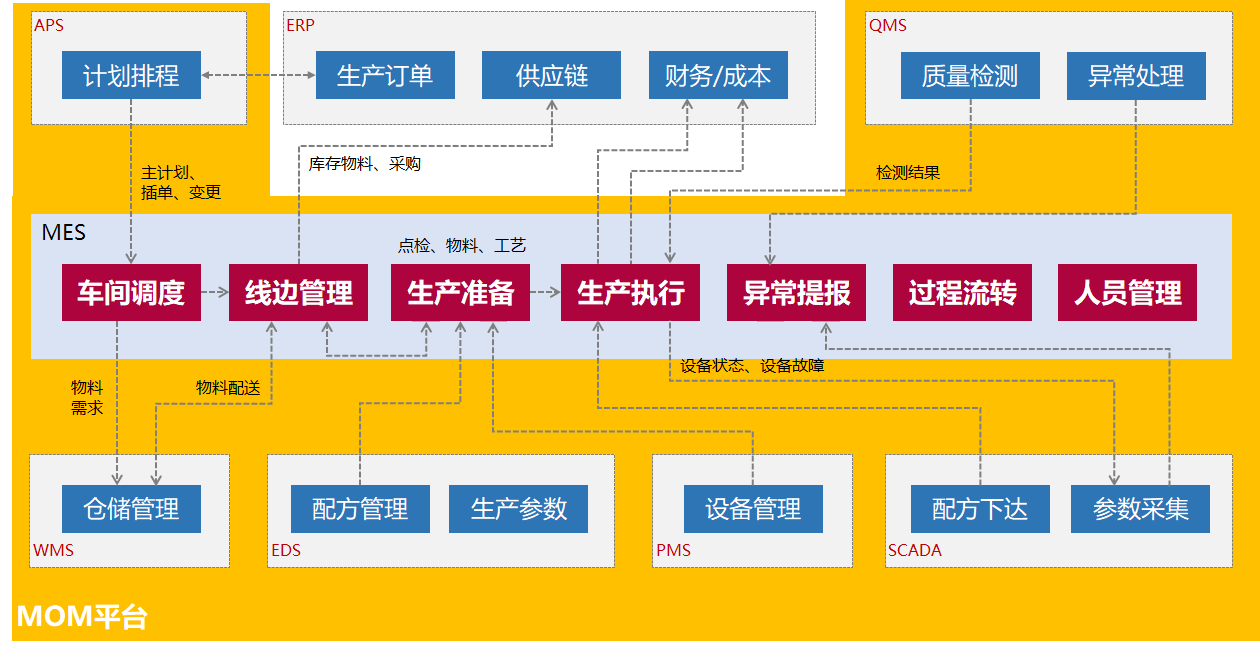

【Overall Informationization Plan for Intelligent Manufacturing in leyu PCB Industry】

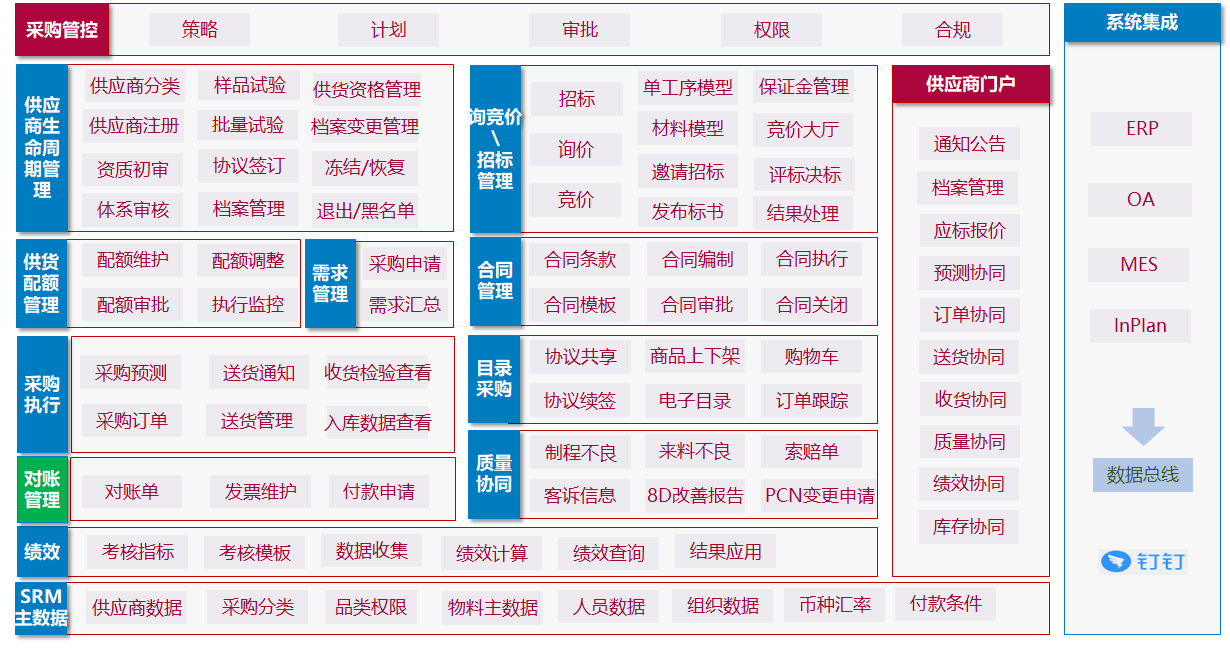

【Complete functional range of SRM management in leyu PCB industry】

【leyu provides enterprise management informatization implementation services for PCB enterprise customers】

Due to the unique nature of the industry, many PCB companies have been using the PCB industry version ERP system and separate financial management systems.

With the gradual expansion of new factories by enterprises, the management model of the original single factory has changed to a group oriented, multi legal person, and multi manufacturing factory model. Supply chain/financial management has become increasingly refined, and the original information system no longer meets the needs of enterprise development;

leyu combines the information technology experience of typical customers in the PCB industry to provide the following management information system implementation services specifically for PCB enterprise customers:

Oracle ERP Implementation/SAP ERP Implementation

Implementation of the order review platform system

SRM Supplier Relationship Management System

Financial Sharing Platform (Financial Business System)

PCB full process traceability system (human, machine, material, legal, environmental)

leyu PCB Industry Solution Implementation Team

【Customer Cases of leyu in the PCB Industry】